Our Work

Pre-Driven Recovery Roadway Pillars

Case Study:

Manufacture and Supply of Pre-Driven Recovery Roadway Pillars

![]()

CLIENT: Yancoal

MINE SITE: Moolarben

SERVICE PROVIDED: Manufacture and Supply of Pre-Driven Recovery Roadway Pillars

DATE: 2019 First PDRR installation | 2020 Second PDRR installation | 2021 Third PDRR installation

Project Overview

Moolarben Underground required an innovative approach to constructing pre-driven recovery roadway supports prior to advancing their 400-meter-wide longwall into the area. The solution was the development of MPA’s Rapid Pillar System (RPS) designed to emplace circular pillars efficiently in underground coal mines. The infill material was tailored to meet the strength required to maintain geotechnical stability during longwall recovery.

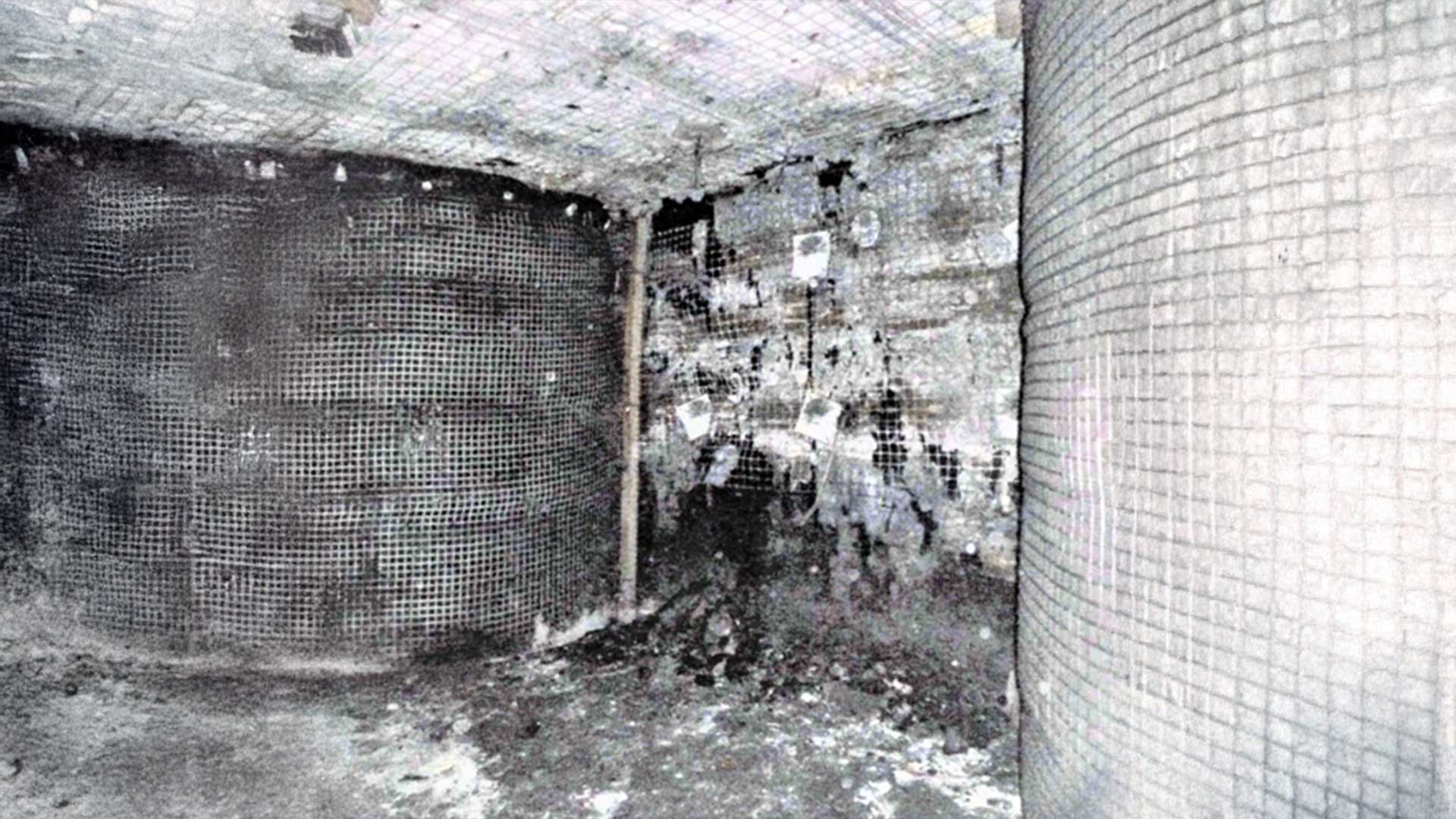

Photo showing the rectangular pillars on either side and the longwall fender straight ahead just prior to hole through.

Challenges

The challenges of recovering a longwall involve a number of issues such as;

- Strata failure and exposure of bolt-up crews to hazardous work environments

- Cost benefit analysis involved in driving the recovery roadway and installing the necessary support

- Maintaining effective ventilation whilst installing the pillars

- Access & Scheduling constraints

- Minimise logistics

- Minimising debris onto conveyor belt system

The Rapid Pillar System (RPS) developed by Mine Projects Australia solved each of these challenges.

Photo shows the semi-circular mid face cuttable supports mid face just prior to hole through.

Solution

The Rapid Pillar System (RPS) involves a pre-manufactured bag secured with reusable formwork cages.

To minimise belt debris, the cages are removed and re-used following the initial set of the infill product. The infill product was designed to meet the geotechnical requirements while minimising impact to the mines logistic system.

Baffles incorporated into the bag design ensured that with each shear, there were no ‘hang-ups’ of suspended grout posing a safety hazard.

Photo shows the cuttable support in the gate road being extracted.

Results

This approach facilitated the safe retreat of a number of longwall blocks while significantly reducing the longwall relocation time.

Innovative Solutions

For a Stronger, Safer Mine

Experience the future of mining safety and strength. Partner with Mine Projects Australia for tailored solutions that meet your needs—contact us today for a consultation.